Industry Leading PVD Coating

Gold and coloured components are finished using controlled PVD coating processes. This method provides a consistent surface finish, improved adhesion, and increased resistance to wear compared to conventional plating.

Coating thickness and colour uniformity are monitored throughout the process to ensure long-term durability and visual consistency.

Brass Watch Needles

Watch hands are produced from solid brass and shaped to precise dimensions. Each hand is finished to ensure accurate alignment, consistent colour, and smooth surface quality.

Final polishing and coating are applied to maintain clarity and long-term stability.

Glossy Rolex Dials

Gloss-finish dials are produced using multi-stage surface treatment processes. These include controlled machining, polishing, and coating to achieve a smooth, reflective finish.

Dial printing and markers are applied with precision to ensure correct spacing, alignment, and legibility.

Metallic Rolex Dials

Metallic dials are manufactured using refined brushing and finishing techniques to achieve uniform texture and colour depth. Surface treatments are applied to enhance contrast and improve long-term appearance.

Indices and logos are applied with exact placement to match original design specifications.

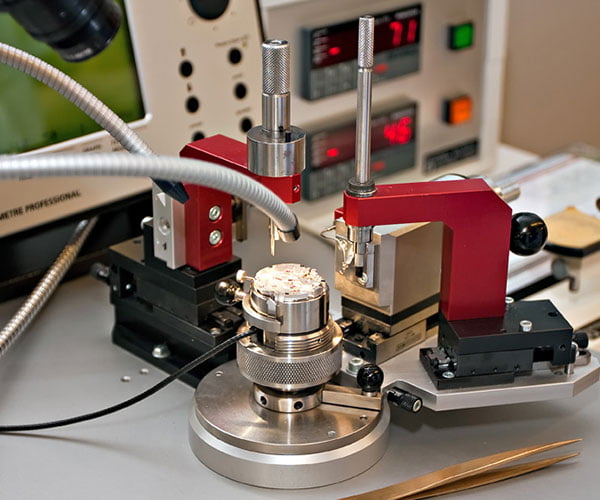

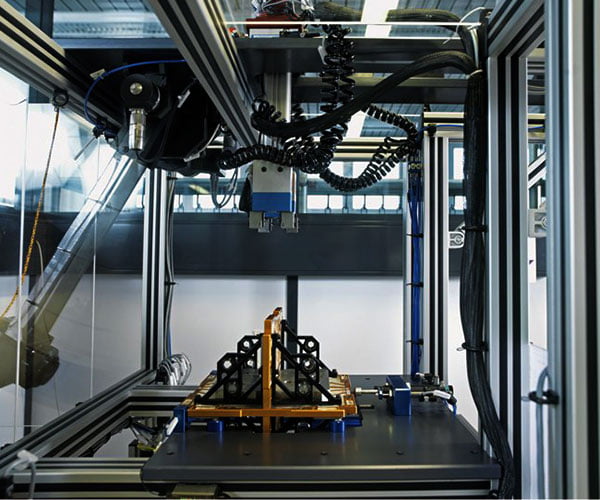

Modern Technology for Handcrafted Timepieces

Assembly combines skilled manual work with modern tooling and measurement equipment. Precision instruments are used to ensure accurate installation of components and correct tolerances.

This approach allows consistency while maintaining careful attention to detail during assembly.

Environment Monitoring

Assembly environments are carefully controlled for temperature, humidity, and air quality. Stable environmental conditions help ensure consistent results during movement assembly and casing.

This reduces variability and supports reliable long-term performance.

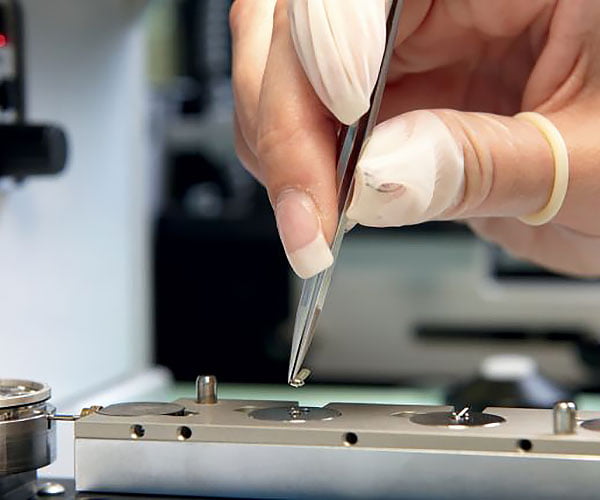

Highly Accurate Swiss Assembly

Each movement is assembled and regulated by trained technicians. Dial and hand installation is performed using alignment tools to ensure correct positioning and clearances.

Cases are sealed following assembly to ensure proper fit and structural integrity.

Top Quality Elements

High-quality components are used throughout assembly, including sapphire crystals, ceramic bezels, and Super-Luminova treated hands and markers.

Component selection focuses on durability, performance, and visual accuracy.

Geneva-Based Operations

Assembly and quality control processes are overseen within a Swiss-controlled environment. Workflow systems track each stage of assembly to maintain consistency and traceability.

This ensures production standards are applied uniformly across all models.

COSC-Compatible Regulation Standards

Movements are regulated to meet defined accuracy targets consistent with Swiss mechanical watch standards. Timekeeping performance is measured and adjusted prior to final casing.

This process ensures stable and predictable operation under normal use.

Testing Procedures

Each assembled watch undergoes functional testing, including movement operation, hand alignment, crown function, and winding performance.

Only watches that meet defined quality criteria proceed to final inspection.

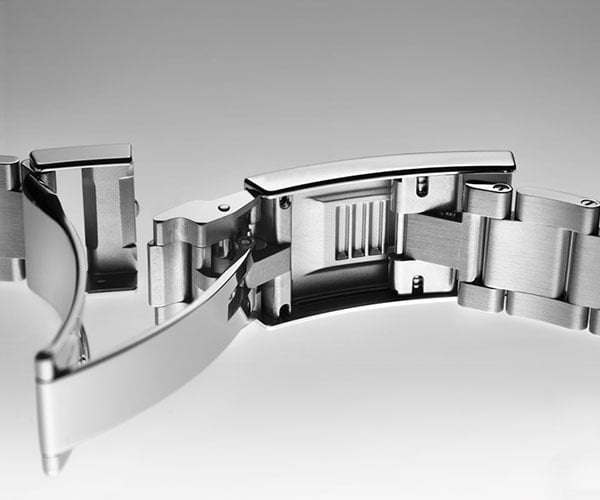

Finishing Touches

Final inspection includes visual assessment, functional testing, and verification of assembly details. Case finishing, bracelet fit, and overall presentation are reviewed before packaging.

Each watch is approved only after meeting both mechanical and aesthetic standards.