Replacement Parts Availability

A comprehensive inventory of replacement components is maintained to support servicing and repairs. This allows worn or defective parts to be replaced without unnecessary delay.

Access to appropriate components ensures repairs can be completed accurately and efficiently.

Initial Assessment and Demagnetization

Each watch is first assessed by a trained technician. As part of the inspection process, the watch is demagnetized to eliminate any magnetic interference that could affect movement performance.

The movement is then removed from the case for closer examination.

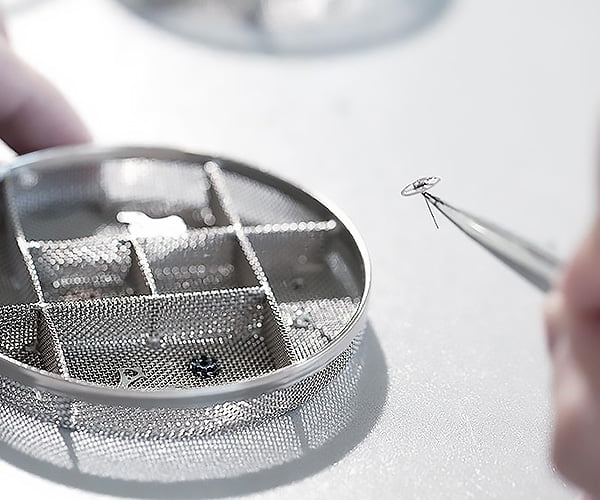

Deep Cleaning Process

Following inspection, the watch is fully disassembled. Individual components, including case parts, seals, and movement components, are cleaned separately using controlled cleaning methods.

This process removes debris, residue, and old lubricants before reassembly.

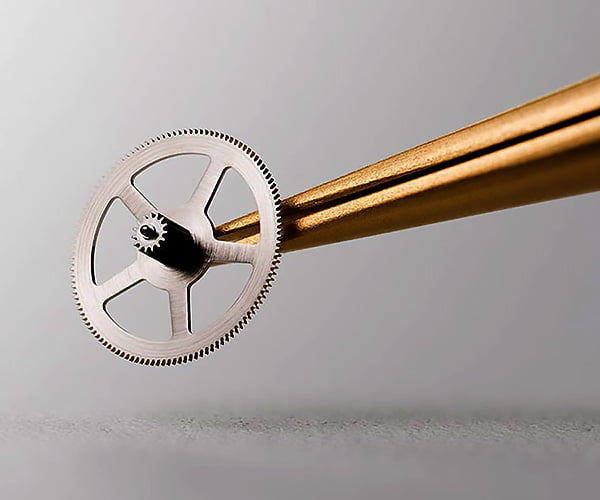

Movement Repair and Maintenance

Movement components are examined individually to identify wear or damage. Defective parts are replaced where necessary, and the movement is cleaned and reassembled.

Fresh lubricants are applied to ensure smooth operation and reduce long-term wear.

Adjustment and Regulation

Once reassembled, the movement is adjusted and regulated to meet defined accuracy targets. Timekeeping performance is checked and refined before casing.

This ensures stable and reliable operation under normal conditions.

Final Assembly and Testing

After regulation, the movement is returned to the case. New seals and gaskets are installed where required, and the case is securely closed.

The watch then undergoes functional testing to verify correct operation, sealing integrity, and overall performance.

Final Inspection

Each serviced watch is inspected visually and mechanically before approval. This includes checks of timekeeping accuracy, crown function, hand alignment, and general finish.

Only watches that meet quality standards are approved for return.